A question that is often asked is “are load notices required on my storage equipment”. To answer this you first should know what they are and why they are needed. Load notices are signs which tell users how to use and how not to use their shelving or racking systems and specifically how much weight can safely be loaded onto the system. These notices give vital safety information and when clearly displayed and combined with the correct training, give businesses the reassurance that staff are informed about how to safely load their storage systems. In worst case scenarios, over-loaded pallet racking can cause catastrophic and even fatal collapses. Contact us today to order your warehouse load notices on 0800 6123210, our sales team are happy to help!

A load notice is normally fixed to the outer structure of the pallet racking (usually the frame or upright at the end of a run). Ensure they are secured with permanent fixings that keep them correctly positioned on the structure, such as screws or plastic ties. Avoid using something that allows easy removal, like clips or magnets.

Do I Need Load Notices and How Many Do I Need?

SEMA Codes and HSG 76 are guidance documents, not legal requirements. Displaying SEMA load notices on your pallet racking isn’t mandatory by law but it is the industry standard method to show compliance with Health and Safety legislation. Without clear load notices, you risk non-compliance and serious consequences if an accident occurs.

There is no specific guidance on the amount of load notices required however signs should be visible and should clearly state which pallet racking they refers to. There is an obligation for the employers to ensure that their employees are covered by PUWER (Provision and Use of Work Equipment Regulations 1998). Regulation 4, requires every employer to ensure that work equipment is appropriate for the required operation. Pallet racking is classified as work equipment. It is crucial to health and safety that the pallet racking system installed can support the loads required of it and that these loads are clearly displayed.

As an example, if a whole of a block of pallet racking in a single warehouse is serviced through a single door and is all to the same configuration, a single sign on entry might be deemed acceptable as all drivers will see if as they enter the warehouse.

However, if every run of pallet racking has a different configuration then you can tackle this in a couple of ways:

- A different load notice for each configuration. However this would need to be clear which load notice relates to which bays.

- One load notice that gives an acceptable solution for all configurations in that run. This would need to be based on the worst-case (weakest) configuration of that run.

What Information Should Be on a Load Notice?

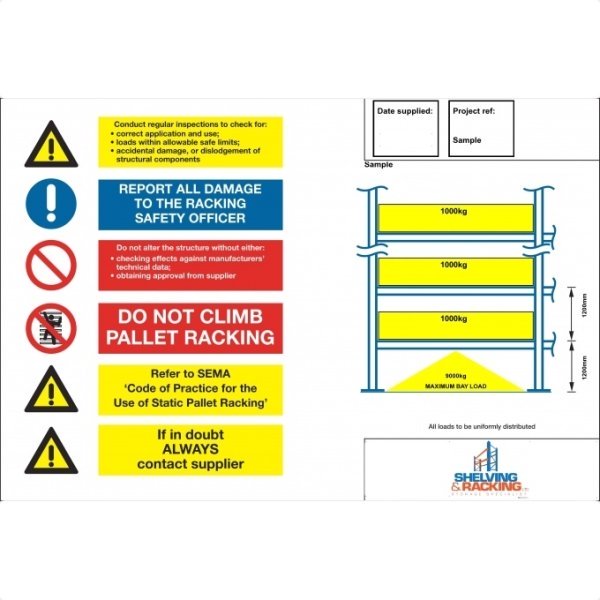

It’s challenging to balance the amount of information on a notice with the likelihood that people will read it. Too little information and important points might be missed; too much, and no one will read it. The load notice aims to balance this. By providing key safety messages and specific information that is easily read by workers during their normal duties. It doesn’t cover every safety detail and doesn’t replace any formal training required.

The design of the load notice on the pallet racking should contain, as a general rule the following elements. Safety and prevention warnings, the load capacities, and the contact details of the manufacturer and distributor for the end customer.

- Signage in accordance with the Safety Signs and Signals regulations.

- Brief description, comments of the system (usually includes the manufacturer of the system installed).

- Maximum load per beam level (UDL).

- Height from the floor to the top of the first beam level.

- Height from the top of first beam to the top of the next level.

- Maximum bay load, including all levels.

- Space for supplier information of the storage system.

What should I do if my pallet racking doesn’t currently have a load notice?

The load capacity of pallet racking systems varies significantly. Factors like steel grade and thickness, configuration (number of beams per bay, height to the first beam, beam pitch, number of bays in a run), and floor fixing type all influence the maximum load capacity. Therefore, you would need to consult the company that the pallet racking was purchased from. If you do not know where the pallet racking was purchased from you could either get in touch with the manufacturer or consult a trained professional to ensure the information is accurate.

In summary, to answer the question are load notices required on my storage equipment? Simply the answer is yes, if you are to adhere to the legislation set by SEMA, HSE and PUWER.

To order your load notices today, please contact a member of our sales team on 0800 612 3210.

Cart