Pallet racking is essential for efficient warehouse operations. Proper storage helps save time and money, boosting profits. Safe and secure pallet racking is vital for many businesses. Maintaining your pallet racking can prevent costly issues. In this blog, we’ll discuss pallet racking, inspections, and tips in maintaining your pallet racking between inspections. If you have any concerns with your pallet racking you can contact us on 0800 6123210, we are happy to help!

What is pallet racking?

Why should you have your racking inspected?

Health and safety are crucial in any workplace. They ensure physical safety for everyone and protect against the complications of paperwork and consequences if an accident occurs. Good health and safety practices also provide peace of mind, improving mental health and emotional well-being.

In a warehouse, maintaining your pallet racking is vital for health and safety. Regular use and handling of heavy items cause wear and tear, which can lead to serious problems if not addressed. Regular inspections help catch issues early, allowing for timely repairs and preventing larger problems. Inspections also promote accountability and emphasise the importance of pallet racking maintenance as a team effort.

What can you do between inspections?

You should schedule regular inspections, either annually or every six months, for a SARI approved inspector to check for any signs of damage before they become serious issues that could lead to accidents, injuries, or costly damage to your stock.

In addition to these official inspections, there are several steps you can take in maintaining your pallet racking between inspections.

In house inspections

What should you look out for?

Signs of corrosion

Forklift damage

Forklifts can cause significant damage to your pallet racking, even if the impact seems minor. A collision can compromise the pallet racking’s structural integrity, so it’s crucial to monitor any forklift incidents. Even a small bump can have serious consequences.

Keep detailed records of any collisions, noting the location of the impact on the pallet racking. This, combined with regular visual inspections, helps monitor the stability of your storage system.

Bends and dents

Bends and dents in your pallet racking can create hazards for everyone using the shelves. These deformations can misalign the structure, increasing the risk of it toppling over. They can also tilt your pallets, complicating picking and packing, and making your stock more likely to slide off.

While some dents and bends might be smoothed out, these areas remain weak points. It’s safer to replace any damaged components to maintain the integrity of your pallet racking system.

Missing beam locks

Beam locks are designed to keep your pallet racking secure. If any are missing, they should be replaced immediately. Occasionally, a beam lock might go missing, so regularly checking and counting them to ensure they are all in place is crucial for maintaining safety and preventing issues from arising due to a missing clip.

Overloaded racking

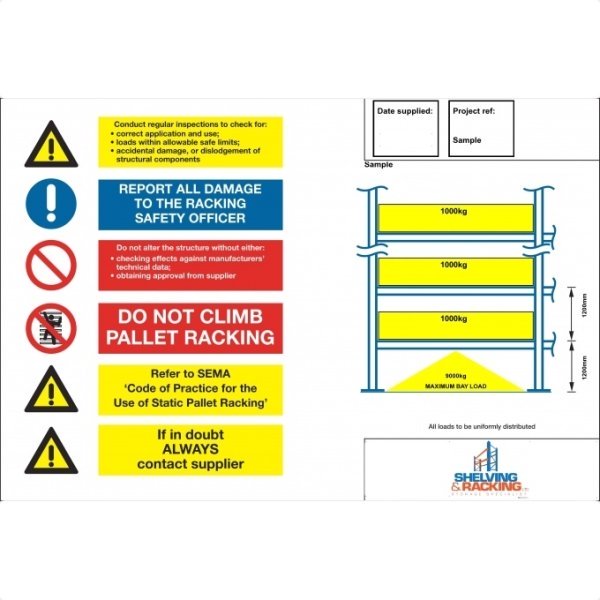

Every pallet racking unit has a maximum load capacity that must be adhered to for safety. It’s essential that your team is aware of these limits and respects them consistently. Overloading a racking unit can cause it to buckle or collapse, so it’s critical to prevent accidental overloading of your pallet racking.

While it may be challenging to visually identify overloading, knowing the weight limits for each pallet racking unit and organising your stock accordingly helps ensure that you do not exceed these limits.

Dislodged beams

Similar to dents and bends, dislodged beams can disrupt the alignment of an entire pallet racking system. Even a minor impact can knock a beam out of place, compromising the stability of the entire unit. Performing frequent and regular checks on all beams allows you to promptly identify and correct any that have become dislodged before they escalate into serious issues.

Damaged or twisted uprights

The base of your pallet racking is prone to damage because it’s often at a height that can be accidentally bumped or hit by forklifts, feet, and stock. Unfortunately, damage to the base can have significant consequences for the entire pallet racking system.

It’s crucial to regularly assess the condition of the base of your pallet racking units, paying close attention to any signs of twisting or unusual angles at the feet. Undetected damage that is then struck again could destabilise the entire unit, potentially causing it to topple over. This not only risks damaging stock and other pallet racking but also poses serious injury hazards to nearby workers.

Racking protectors

You can enhance the safety of your pallet racking units by installing different types of racking protection. These include barrier systems and upright protectors that act as physical barriers, shielding your pallet racking from forklift damage. Additionally, support bars and back stops can be installed on pallet racking shelves to prevent pallets from sliding off.

Staff training

Making sure everyone who works on-site is familiar with the danger signs we’ve outlined in this blog is a great way of avoiding serious incidents with your pallet racking. The people who are most frequently in contact with your pallet racking will often be the first to spot any damage or differences. Therefore, giving everyone training in what to look out for and report is essential. It’s also really important to make sure all your staff know the maximum loads for all of your pallet racking so they don’t overload them.

SEMA offer a Rack Safety Awareness course designed to help you to identify any issues that may arise. The course offers advice on how to comply with the law, conducting risk assessments, recording an (in house) inspection, reporting damage levels and action points.

For more information or advice on maintaining your pallet racking between inspections, feel free to get in touch with our team on 0800 612 3210. We can help to identify and fix any trouble spots, and can offer advice on extra precautions to make your warehouse a safer, and more efficient, place to work.

Cart