What is pallet racking?

Warehouses worldwide use adjustable pallet racking (APR) as the standard for storing palletised goods. It is a modular structure assembled using upright frames and horizontal beams. Buy here.

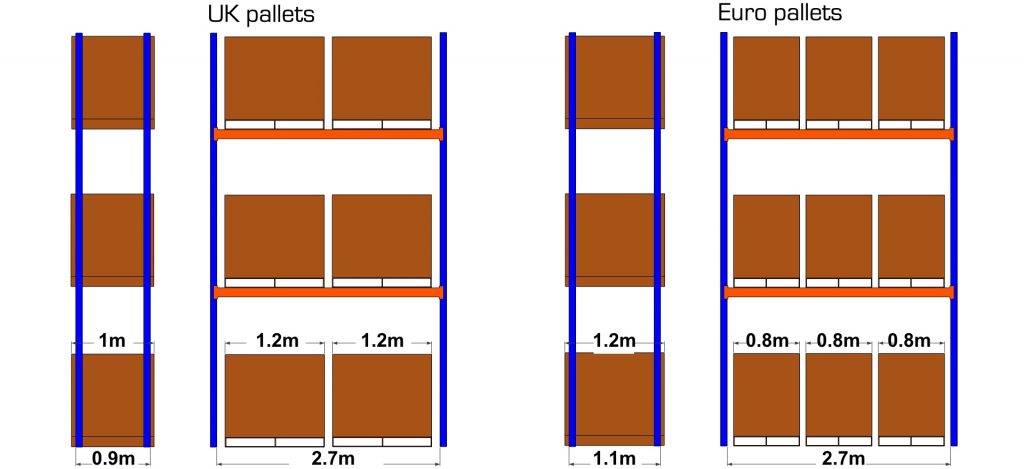

A forklift truck places pallets onto the beams in such a way that they overhang 50mm to the front of the racking and 50mm to the back. This allows a little leeway for placement. If your pallets are 1000mm deep you need 900mm deep frames. If your pallets are 1200mm deep you need 1100mm deep frames.

Call us on 0800 612 3210 for quotes or send us a message on our enquiry form.

Pallet Racking Dimensions

There are several standard sizes for pallet racking frames and beams and bespoke options available for unique and unusual loads.

Storing UK pallets

Standard UK pallets are 1200mm x 1000mm and a forklift picks them up on the 1200mm side and places them 1000mm deep onto 900mm deep pallet racking, allowing for a 50mm overhang to the front and back

Storing Euro Pallets

Standard euro pallets are 800mm x 1200mm and a forklift picks them up on the 800mm side and places them 1200mm deep onto 1100mm deep pallet racking, allowing for a 50mm overhang to the front and back.

Storing non standard pallets or loose items

If you use unusual pallet sizes, or a mixture of different pallet sizes or if you are storing non palletised goods. Timber decking or wire mesh decks create a shelf level between the beams. Your pallets do not need to over hang the beams if you have decking but it is important that the decks are strong enough to take the load.

What beam length should I choose?

This depends on the size and weight of your pallets. A standard beam length is 2700mm clear entry (between the upright frames) and will accommodate 2 UK pallets or 3 Euro pallets and these beams would typically take 2000kg – 3000kg per level. Longer beams are available as are smaller single pallet beams.

Pallet racking configurations

There are several different ways to configure pallet racking depending on the density of storage required and the fork truck you use. All the below options use the same racking components but different configurations. Always refer to the technical specifications provided by the forklift manufacturer.

Wide aisle

Aisles of between 2.5m and 4m depending on the style of truck used. A counterbalance truck will need more clearance than a reach truck.

Narrow aisle

Narrow aisles are between 1.8m and 2.3m and can considerably increase available storage area. This configuration requires narrow aisle forklift trucks which also have the advantage of being able to lift pallets higher than counter balance trucks increasing vertical storage.

Very narrow aisle (VNA)

With aisles as small as 1.6m VNA systems are the answer for warehouses where space is at a premium. It is necessary to use very narrow aisle trucks and to fit guide rail or a wire guidance system.

Back to back

When 2 runs are placed side by side so each run is accessed from a different aisle. Frame spacers of 200mm or 300mm are used to separate the frames. This allows the required clearance between pallets when the racks are loaded. This is a common layout for wide aisle, narrow aisle and VNA systems.

Double deep

Double deep racking is higher density option where a specialised truck with hydraulic or telescopic forks can reach over the 1st run of racking to place a pallet on the one behind. This option further reduces the number of aisles required.

Alternative racking systems

Cantilever Racking

Used for storing long items like tubes, pipes and profiles or large sheet materials. Cantilever racking is a modular system with arms that clip or bolt in to upright legs to provide uninterupted horizontal storage.

Drive in Racking

A modular structure creating a high density ‘block’ of racking. No aisles are required as the truck drives through the lane to place pallets on the rails. Drive in racking is often placed against a wall and accessed from just one side meaning pallets are stored ‘Last in first out’ (LIFO)

Drive though Racking

The same as drive in racking but accessible from both sides so pallets can be stored ‘First in First out’ (FIFO) as a result you achieve improved stock rotation and eliminate difficult to access pallets.

Push back racking

A dynamic system where the forklift places pallets onto the top of several nested carts. The cart holds the pallet and is pushed back when the next pallet is loaded into the same lane. Multiple pallets can be stored on each lane and due to the incline of the rails pallets are automatically presented to the front of the aisle for easy collection.

Pallet Live

‘Pallet live’ or Gravity Flow racking’ uses inclined lanes and rollers so loaded pallets travel down the lanes to the picking location. It is a FIFO process (first in first out) and ideal for high volumes of time sensitive or perishable goods.

Mobile Pallet Racking

An extremely high density option where the warehouse operative controls movable beds with runs of pallet racking mounted on them. The closely packed racking moves to create aisles where required, maximising floorspace.

Cart